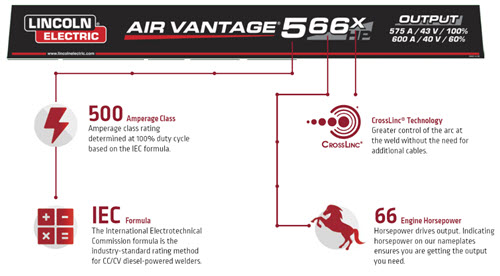

Lincoln Electric Air Vantage® 566X (Deutz®) (T4F Compliant) - K3242-3

-

Top Features

- Powerful 575 amp welder, 20 kW generator, and 60 cfm air compressor

- CrossLinc® enabled to help improve safety, quality, and productivity

- Rugged design for the harshest environments

- ArcLink® capable for advanced welding processes

Processes

SMAW (Stick), FCAW (Flux-Cored), GMAW (MIG), GMAW-P (Pulsed MIG), GTAW (TIG), CAC-A (Arc Gouging)

$54,995.00

On Demand Versatility

The Air Vantage 566X is a powerful multifunction machine that offers 575 amps of IEC rated welding output, 20 kW of auxiliary power, and 60 cfm of compressed air in a single package. This 3-in-1 workhorse has been designed to meet the most challenging job site needs and environments. The rugged Air Vantage 566X can handle a challenging assortment of tasks from heavy-duty carbon arc gouging to pulse welding. Now better than ever, the machine features CrossLinc® Technology to provide welders with greater control at the arc to help improve safety, productivity, and weld quality. Purchase this powerhouse today!

Product Highlights

Multifunction Machine

- Welder – IEC rated at 575 amps of welding current to tackle numerous welding and carbon arc gouging applications

- Generator – 20 kW of continuous three phase power to run industrial tools such as plasma cutters, pumps, or inverter welders

- Air Compressor – 60 cfm @ 100 psi of compressed air powered by VMAC®

CrossLinc® Enabled¹

- Allows communication through a standard weld cable to enable voltage or current control at the arc without a control cable

- Helps to improve safety, quality, and productivity with less trips to the power source and reduced jobsite clutter

- Utilizes True Voltage Technology™ (TVT) to compensate for voltage drop to further improve operations

Multi-Process Welding

- Select one of five basic process modes including CC-Stick, Downhill Pipe, DC Touch Start TIG®, CV-Wire, or Arc Gouging mode, which maximizes output for up to 3/8 in. (9.5 mm) carbon rods

Advanced Arc Performance

- Expanded welding capabilities with customized modes for stainless, aluminum, and steel as well as advanced SAW and orbital pipe modes²

- Pulse welding capability for better arc control in out-of-position work and low heat input for critical welds²

- Enhanced gouging performance prevents the engine from stalling, resulting in smooth material removal

- Minimized spatter for stick or pipe welding

Reliable Operations

- Lab tested, field proven ruggedness and durability

- Engineered for outdoor use in the harshest environments

- Encapsulated GFCIs, stainless steel paneling, and potted PC boards for added protection and inceased reliability

Industrial Diesel Engine

- 4 cylinder, 65.7 hp, turbocharged Deutz® diesel engine runs smooth and quiet

- Excellent cold-weather starting and high altitude operation

- Standard engine gauges allow you to monitor performance at a glance

- Tier 4 Final Compliant to deliver a 90% reduction in particulate and nitrous oxide emissions

- 25 gal. (94.6 L) fuel tank for longer running time

(1) Requires CrossLinc enabled wire feeder or CrossLinc remote

(2) Requires ArcLink Communications accessory

Changing The Name of The Game

| NET WEIGHT | 1737.00 (787.90 kg) |

-

RATED OUTPUT @ 104° (40°C) IEC Rating – 575A / 43V / 100%

Max Rating – 600A / 40V / 60%OUTPUT RANGE CC-Stick: 30 – 600 Amps

Downhill Pipe (CC): 40 –350 Amps

Touch Start TIG: 20 – 350 Amps

CV-Wire: 10 – 45 Volts

Arc Gouging: 60 – 600 AmpsOPEN CIRCUIT VOLTAGE 70 Max OCV @ 1800 RPM AC GENERATOR AUXILIARY POWER(1) Single Phase: 12 kW Continuous, 120/240V @ 60 Hz

Three Phase: 20 kW Continuous, 240V @ 60 HzAUXILIARY RECEPTACLES(2) NEMA 5-20R (120V / 20A / 1~)

NEMA 14-50R (120/240V / 50A / 1~)

NEMA 15-50R (240V / 50A / 3~)ENGINE MODEL Deutz® TD2.9L4(4) EPA Tier 4 Final Compliant ENGINE DESCRIPTION 4 Cylinder 65.7 hp (49 kW) Turbocharged Water Cooled Diesel Engine OPERATING SPEEDS (RPM) @ 34.8 HP High Idle: 1800, Low Idle: 1525 DISPLACEMENT 178 cu. in (2.9 L)

Bore x Stroke – 3.62 in x 4.33 in (92 mm x 110 mm)CAPACITIES Fuel: 25 US gal (94.6 L)

Oil: 2.25 US gal (8.5 L)

Cooling System: 2.5 US gal (9.5 L)COMPRESSOR MODEL VMAC®(5) S700162 COMPRESSOR DESCRIPTION Belt-Driven Rotary Screw DELIVERY High Idle – 60 cfm @ 100 psi (1.7 cmm @ 6.9 bar) MAXIMUM SYSTEM PRESSURE 150 psi (10.3 bar) COMPRESSOR PROTECTION Safety Relief Valve: 200 psi (13.8 bar)

High Temperature Automatic Shutdown: 290 °F (143 °C)COMPRESSOR CAPACITIES Compressor Oil: 1.1 gal (4.0L)(6) (1) When welding, available auxiliary power will be reduced. Output voltage is within +/- 10% at all loads up to rated capacity.

(2) Circuits cannot be wired in parallel to operate the same device.

(3) Includes width of door. Base width is 31.6” (803 mm)

(4) Engine warranted separately by engine manufacturer.

(5) Compressor warranted separately by compressor manufacturer.

(6) VMAC® synthetic compressor oil recommended for best operation results, or oil approved by VMAC®Net Weight: Machine only – Does not include fuel.

| Weight | 1737 lbs |

|---|