- You cannot add "Lincoln Electric LN-25 Wire Feeder" to the cart because the product is out of stock.

Miller D-74S Dual Wire Feeder - 951204

Out of stock

-

The Miller D-74S dual wire feeder allows two different wire types to be available on one feeder, avoiding downtime from changing spools and drive rolls.

Miller D-74D Dual Wire Feeder 951204

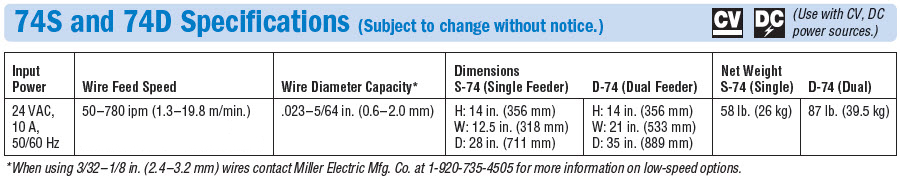

The Miller D-74D wire feeder allows two completely different welding procedures to operate off the same welder without costly change outs. It comes with digital volt and wire feed speed (amp) meters and is capable of remote voltage control. It is a heavy industrial, four drive roll, 24 VAC wire feeder for MIG and flux-cored welding wires. The D-74D feeds .023 to 5/64 diameter welding wire at a wire feed speed range from 50 to 780 inches per minute. It comes standard with trigger hold, dual tension control, automatic run-in, and tool-less rotatable drive. Floating positive drive system provides smooth, trouble-free feeding of a variety of welding wires.

![]()

Processes

- MIG (GMAW)

- Flux Cored (FCAW) (gas and self-shielded)

Applications

Manufacturing Industrial

Heavy Manufacturing

Metal Fabrication

Construction

Light Manufacturing

Features

- Two independent wire drive systems allow two different welding procedures to be performed by the same welding power source without costly change outs.

- Digital meters for easy viewing of the wire feed speed and voltage.

- Remote voltage control allows operator to set voltage at the wire feeder without having to go back to the power source.

- Tachometer feedback to help keep wire feed speed accurate.

- Toolless rotatable drive assembly allows operator to rotate the drive housing, eliminating severe bends in the wire feed path which reduce gun liner life. Also aids in feeding difficult wires.

- Automatic run-in control significantly improves arc starts.

- Trigger receptacle oriented in a downward position to reduce potential damage.

- Trigger hold allows operator to make long welds without having to hold the trigger continuously. Reduces operator fatigue.

- Posifeed™ Wire Drive Assembly Features

24 VDC high-torque, permanent-magnet motor.

Quick-change drive rolls.

Quick-release, calibrated drive-roll pressure adjustment arm allows drive roll change without losing spring preload setting.

Four sealed ball bearing all-gear-driven drive-roll carriers for smooth, positive and accurate wire feed with long uninterrupted service life.

Easy loading and threading of welding wire without having to release the drive-roll pressure arm.

Solid-state speed control and brake circuit eliminates the need for electrical/ mechanical relays and increases service life. - Uses Miller standard 1-5/8 in (41 mm) diameter drive rolls.

- Quick-connect for all Miller guns.

- Covered drive rolls – easy access, heavy-duty, molded composite cover over drive assembly.

- Floating positive drive system provides trouble-free feeding on a variety of wires.

Comes Complete With:

- D-74D Dual Wire Feeder

- Digital voltage and wire feed speed (amp) meter

- Remote voltage control

- Tachometer feedback

- 2 – 15 ft. Bernard® Q-400 MIG Welding Guns

- Two sets of .035 and .045 inch V groove drive rolls

- Standard 10 ft 14-pin interconnecting cord is included

GENERAL SPECIFICATIONS

| Title | D-74D (Dual) |

|---|---|

| Industries Interests | Aerospace Construction Heavy Equipment Manufacturing Infrastructure Manufacturing Railcar Shipbuilding Gtin discontinued SKU: 951204 Category: 17 inch Brands CarouselBlack

esab

hobat

hyper

lincoln

miller

victor

|